Tandem Line Automation Tooling

Tandem Line Automation Tooling

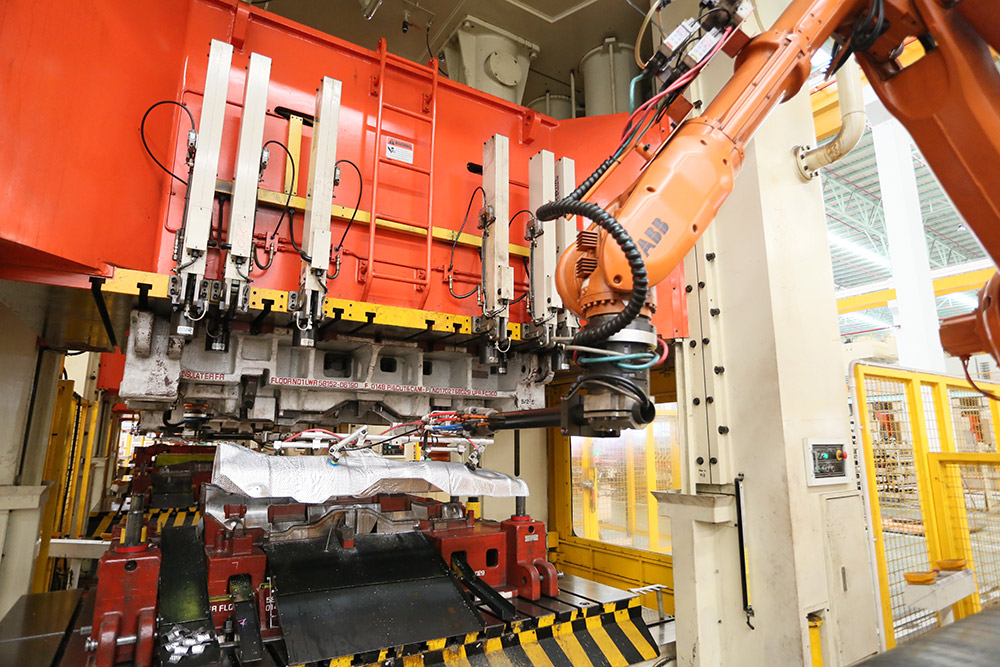

Series stamping line is an automatic production line which is composed of several presses arranged in sequence. A set of mould

(i.e. a process of the production process)is placed on the worktable of each press, and the automatic mechanical arm or robot

completes the loading, transfer of process parts and the loading and packing work.Each process is independently distributed in

each press, and the production line has the highest flexibility. It is suitable for large panel parts with complex production process,

which is conducive to single process debugging and independent production, and is convenient for high quality control of products.

1. Wide range of application, can be applied to the production of all kinds of stamping parts, there is no higher requirement on the

size, shape and thickness of stamping parts, can be applied to the production of large panel parts, with large flexibility.

2. The production efficiency is low. Due to the use of mechanical arm feeding, the beat times can not be higher. Compared with the

progressive production line and multi station production line, the production efficiency is lower.

3. It is conducive to the maintenance and debugging of the mold. Because the clamping and working parameters of each press of

each mold are independent, the maintenance and debugging of each mold process can be carried out independently without

affecting each other.

4. It occupies a large area of production plant. A traditional series production line generally includes 4-5 presses, which covers a

large area.

The end pick-up devices applied by Youya technology in series automation line can be divided into: destacking end pick-up device,

feeding end pick-up device, sequencing end pick-up device and blanking end pick-up device.

Destacking end pickup: it is assembled by vacuum sucker, elastic support rod, double material detection bracket, rotating arm, robot

connecting flange, etc. destacking end pickup can be used for several stamping parts with similar size.

Feeding end pickup: it is assembled by vacuum sucker, sucker connector, rotating arm, main rod of end pickup, main rod connecting

clamp, robot connecting flange, etc. feeding end pickup can be used for several stamping parts with similar size.

Inter sequence end pickup: it is assembled by vacuum sucker, sucker connector, rotating arm / extension arm, main rod of end pickup,

quick change connection of end pickup, etc.

Blanking end pickup: it is assembled by vacuum sucker, sucker connector, rotating arm / extension arm, end pickup main rod, end

pickup quick change connection, etc.

UYA technology has many years of experience in the field of automatic stamping. It can meet all the end pickup standards in the market

(standard series, speedbar, crossbar), and help customers design special mechanisms (sequence flip, rotation, etc.).